NBI Workshops: BIO-BMI-CBMR-IN-KEMI-NEXS

The workshops constitute a framework for the technical environments and functions servicing all research groups and teaching at the participating institutes. We help with development, fabrication, service and running of all kinds of research instruments and teaching equipment.

We interact closely with external suppliers and Science Campus Service when needed.

We have a motto: “We build what you can’t buy”

Where do I go with my task?

If you are planning to enter into project, please contact the Head of the workshops Dennis Wistisen. We will then find the relevant staff member to help you.

Our technical competences span a wide range of knowledge such as:

- Electronics

- Mechanics

- Software

- Vacuum technique

- Low temperature techniques

- Environment instrument requirement surveys (Analysis of vibration, magnetics field and acoustics)

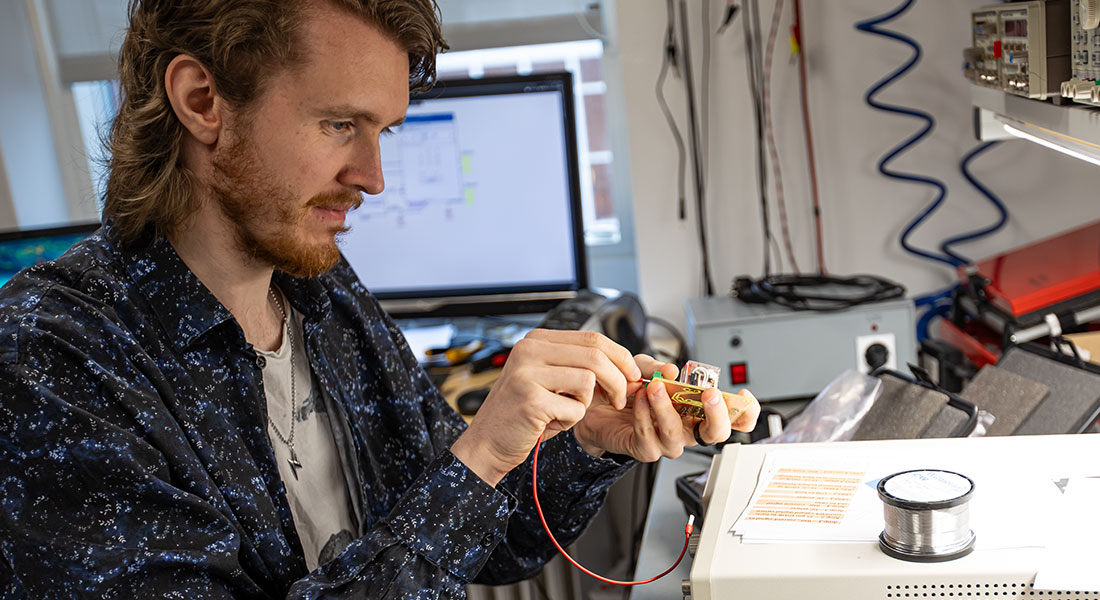

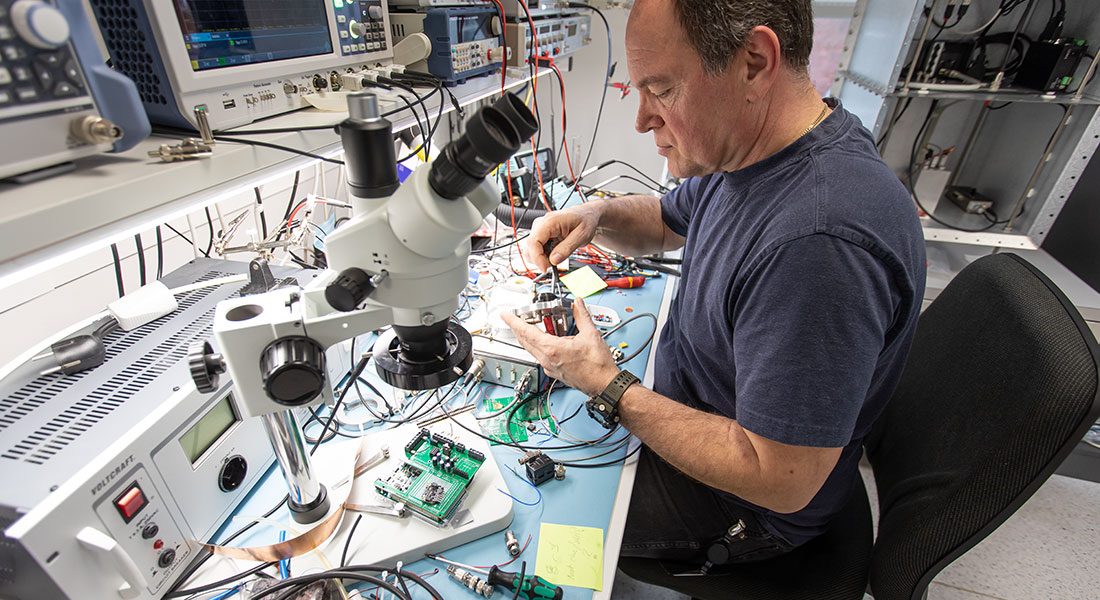

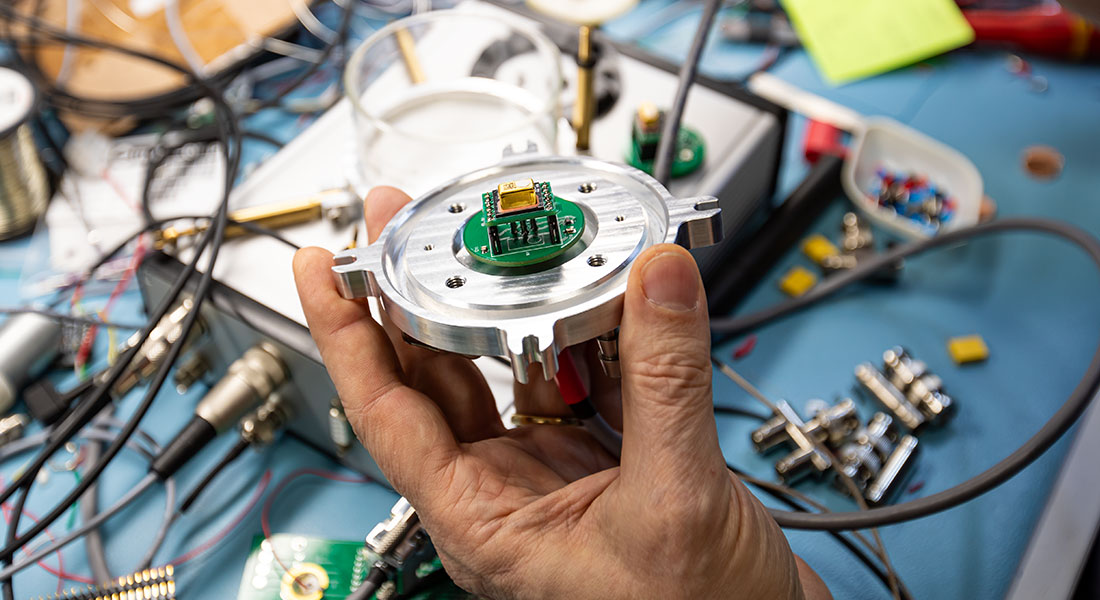

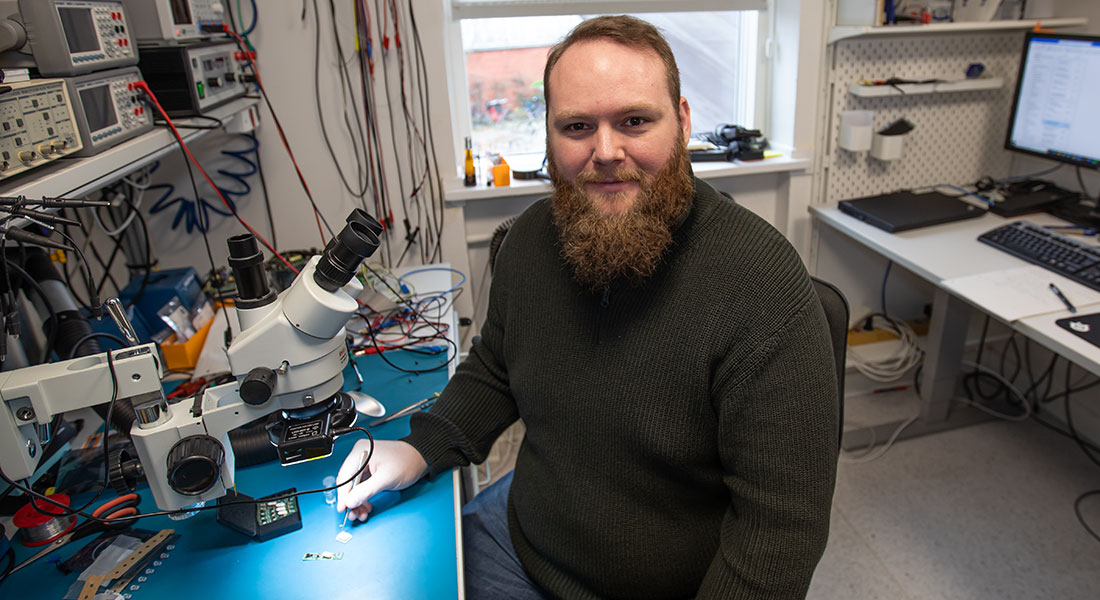

The electronics workshop is staffed with 5 engineers/technicians and 1 apprentice that service the NBI research groups with new designs and repair of existing equipment.

The workshop has a wide expertise with e.g. microcontrollers, analog and digital electronics, data acquisition, control systems and firmware programming.

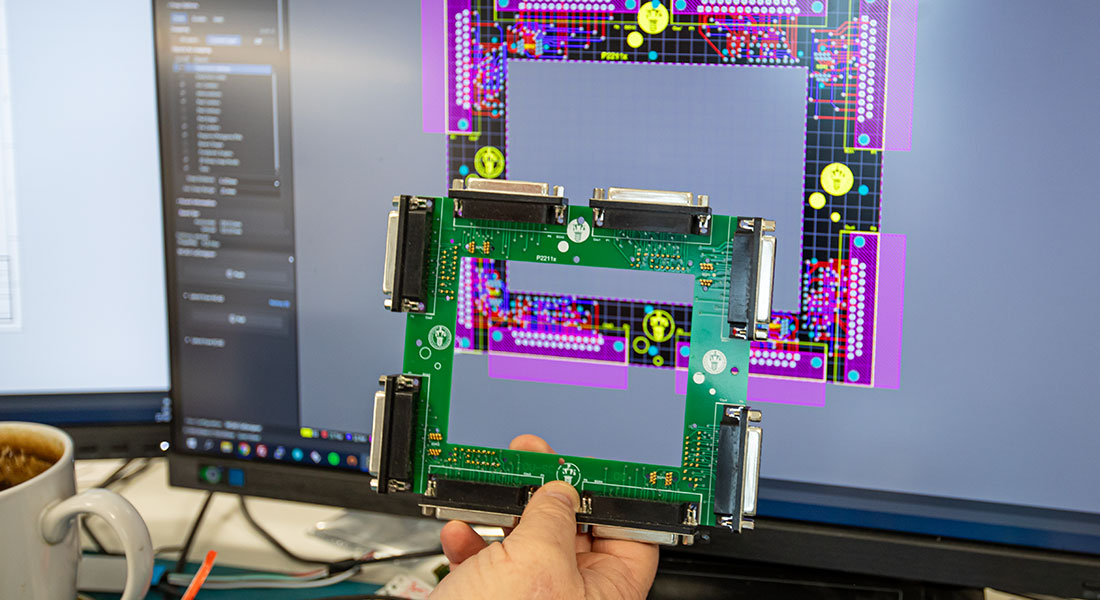

We have small PCB milling machine for 2 layer PCB’s intended for rapid prototyping, and a reflow oven for assembly of PCB’s. For multilayer PCB’s we have good contacts with external suppliers.

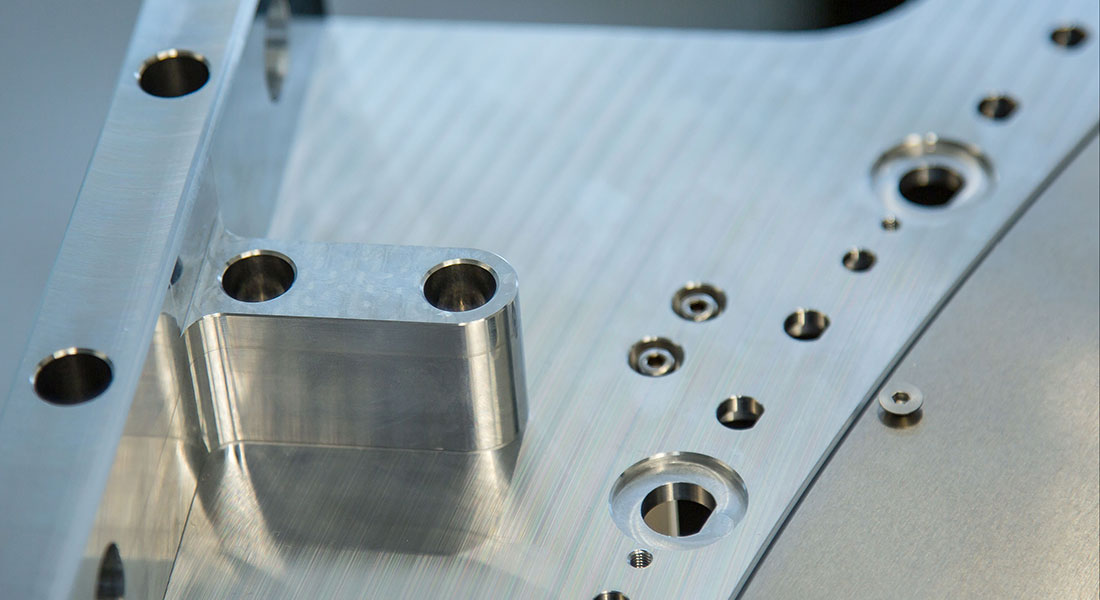

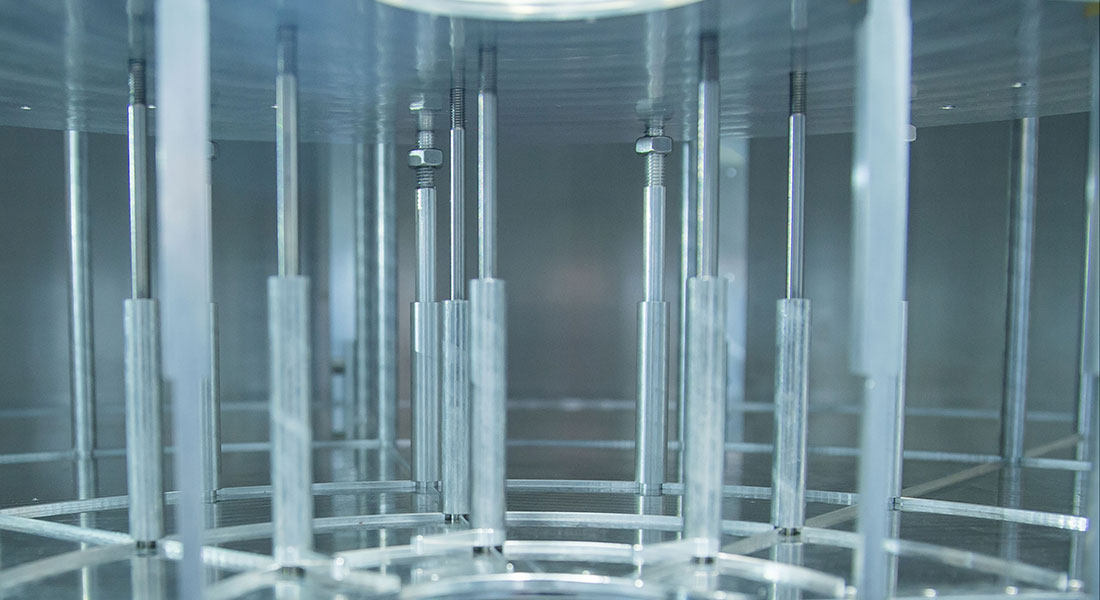

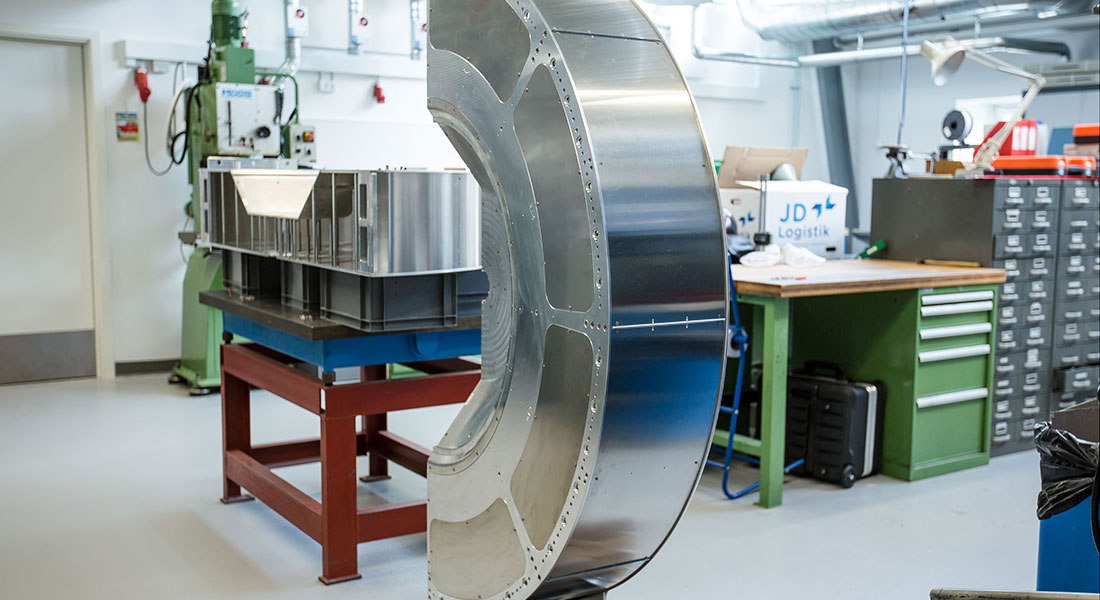

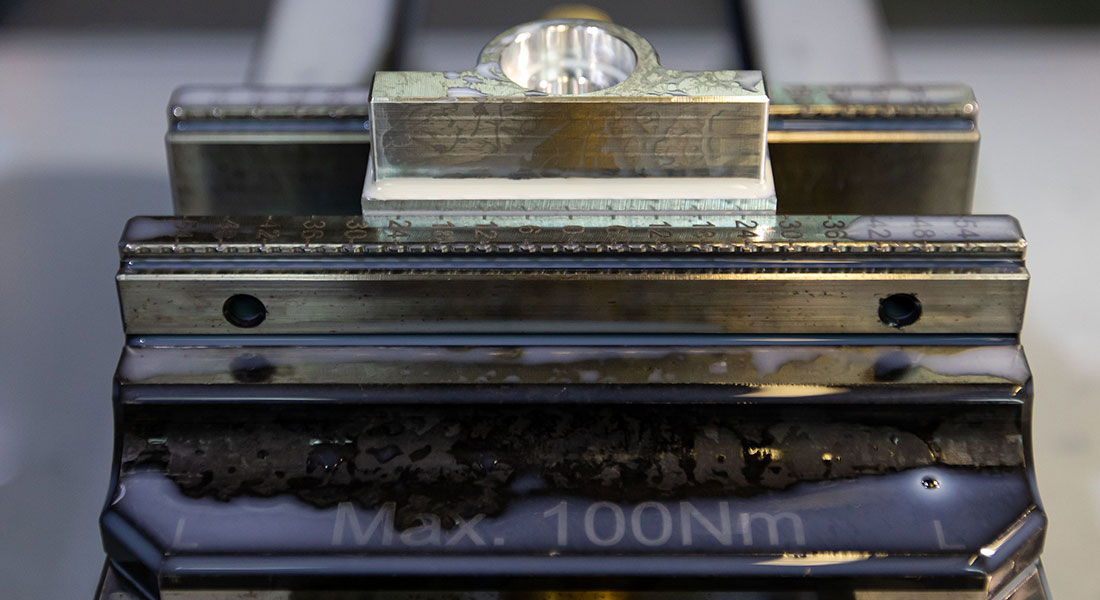

The mechanical workshop is staffed with 9 engineers/technicians and 2 apprentices. The workshop service research groups at the Dep of Biology, Dep of Chemistry and NBI with new designs and repair of existing equipment.

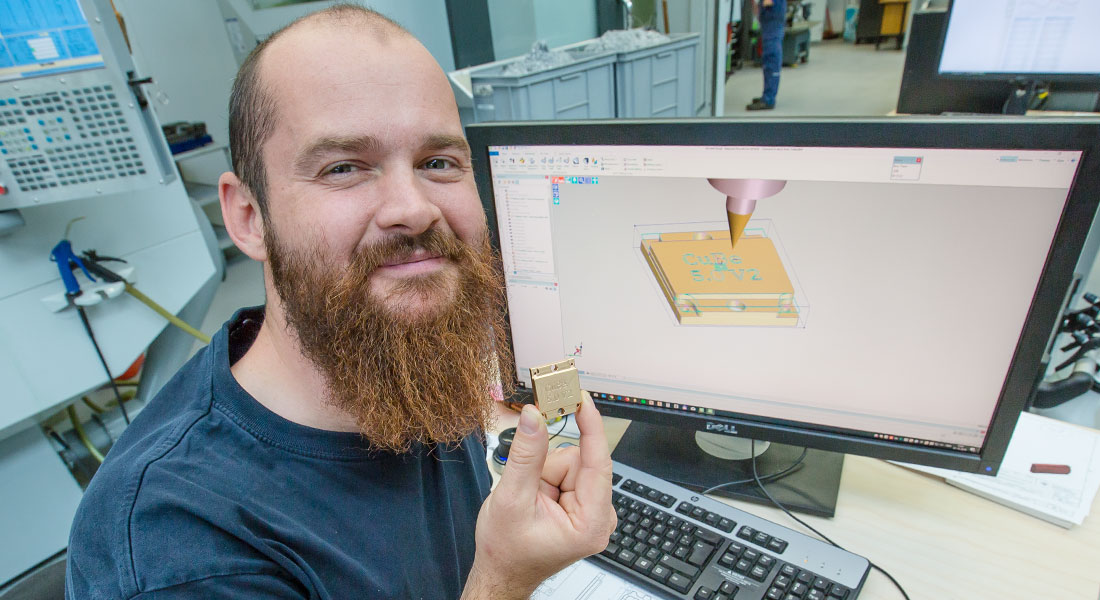

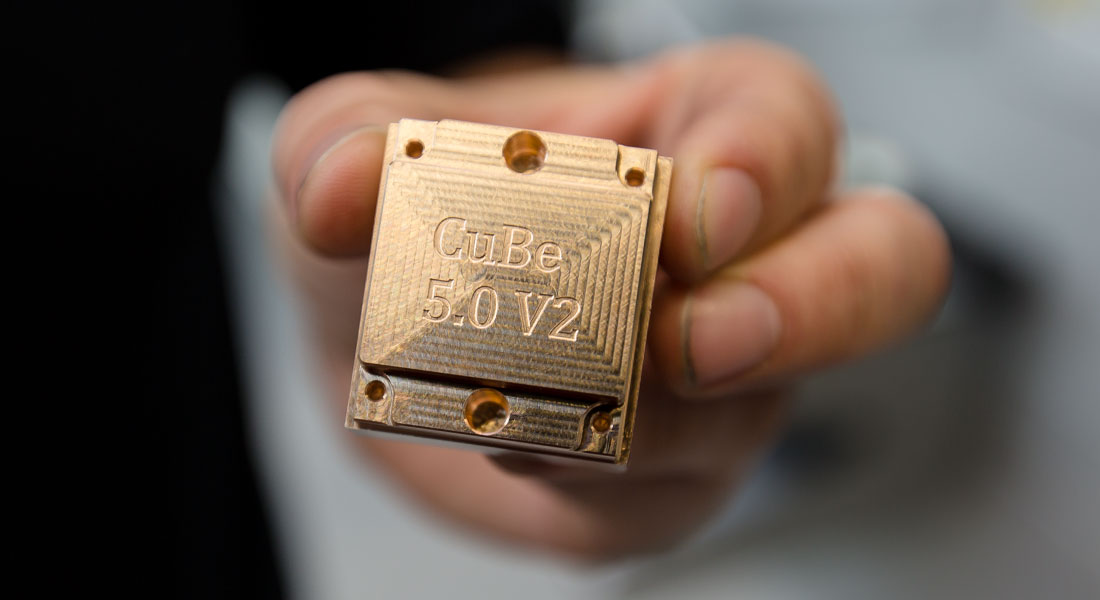

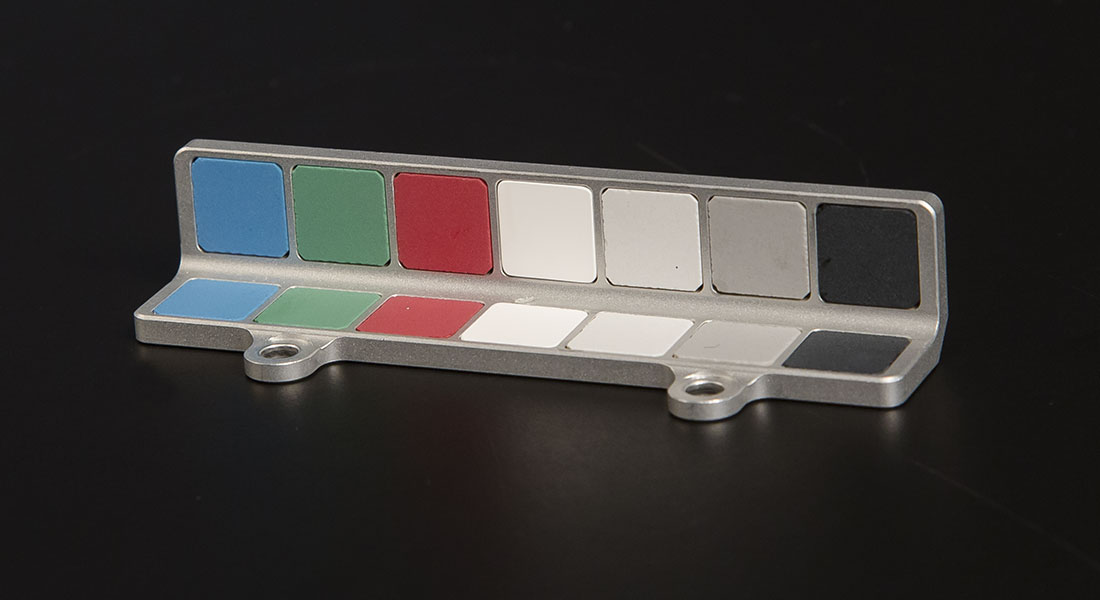

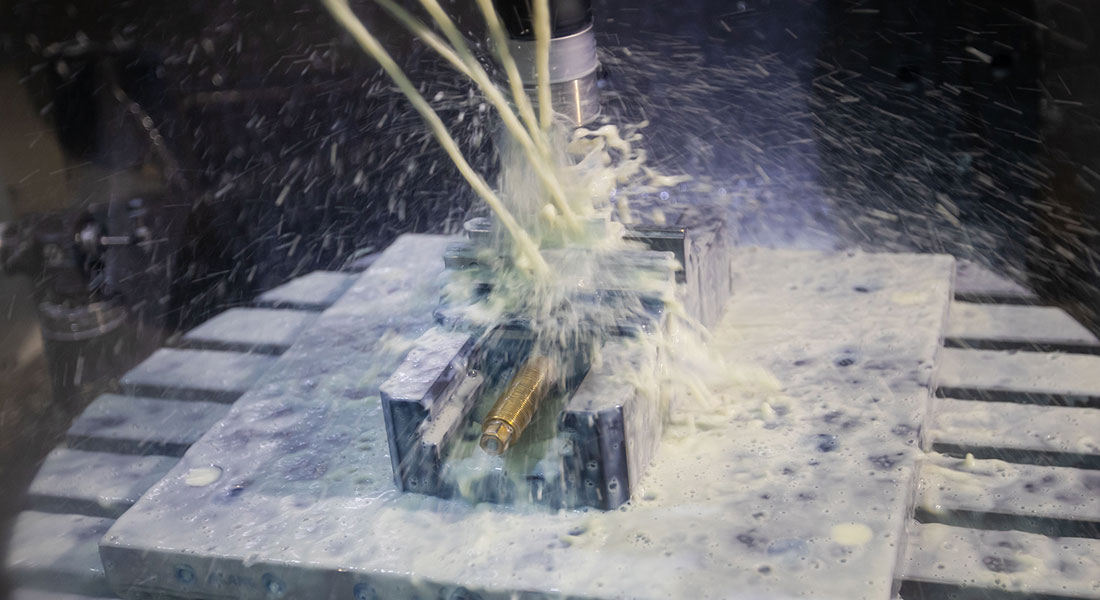

We have a well-equipped machine shop with conventional machines and well as CNC controlled lathes and milling machines. We specialize in building custom made prototypes and small series of mechanical parts.

The workshop has a wide expertise with mechanical design and manufacture of components and equipment using 3D CAD and CAM.

We also do welding and hard soldering of vacuum components for low to Ultra High Vacuum applications.

Manager of the workshops:

Dennis Wistisen

Staff

| Name | Title | |

|---|---|---|

| Search in Name | Search in Title | |

| Anders Palmelund | BSc Engineering |

|

| Baldvin Karel Magnusson | Electronics Technician Trainee |

|

| Bent Neumann Jensen | Research Technician. |

|

| Charalampos Lampadaris | Academic Research Staff |

|

| Cheng Choo Lee | Research Consultant |

|

| Claus Birger Sørensen | Engineer |

|

| Dennis Westphal Wistisen | Research Technician. |

|

| Hauge í Gongini Djernis | Industrial Technician Trainee |

|

| Jonas Riff Larsen | Research Technician. |

|

| Kevin Michael Nikolaus | Special Consultant |

|

| Kristian Ahrenst | Research Technician. |

|

| Matthias Hüther | Special Consultant |

|

| Michael Dahlquist | Research Technician. |

|

| Michael Heide Bernt | Precision Mechanic |

|

| Mikkel Knudsen Edslev | Research Technician. |

|

| Palle Koch | Engineer |

|

| Rasmus Lindegaard Tulinius | MSc Engineering |

|

| Rene Stennow Gotfredsen | Research Technician. |

|

| Rikke Helena Lütge | Electronics Technician |

|

| Simon Alexander Munk Wael Fassel | Engineer |

|

| Smitha Nair Themadath | Special Consultant |

|

| Sune Stausgaard-Petersen | Assistant Engineer |

|

| Søren Børsting | Research Technician. |

|

| Thomas Hedegaard | Research Technician. |

|

| Victoria Jo Thomsen | Industrial Technician Trainee |

|