Ice and Climate participates with a newly developed drilling system in the Antarctic project

The new HT drilling system (right) packed on a Nansen sledge after a test drilling at NEEM in Greenland, 2012. The drill on the left sledge is the old drilling system that is used for the drilling of ice cores of a maximum of 120 m. Even though the new drilling system can drill to a 1000 meter it is still possible to transport all of it on a Nansen sledge.

A completely new drilling system will give faster, easier and cheaper access to good climate data. Through 1 1/2 years of intensive work the Center for Ice and Climate has further developed the equipment to the legendary HT-drill, the Rolls Royce of the ice core drills. Together with an engineer and two scientists from the Centre the new equipment is on its way to the Antarctic where it, during the short arctic summer, is to make a 400 meter deep ice core drilling.

During the six week short summer of 2013-14, the Australian Antarctic Division has planned drilling a 400 meter long ice core in the Aurora Basin North of the eastern Antarctic.

The ice core drilling is part of a plan of the IPICS´ - International Partnerships in Ice Core Sciences - from 2004 where, among other things it was planned to drill a number of intermediate ice cores in the northern as well as in the southern hemisphere. Data from the many ice cores will allow the scientists to map out the parallel climate change in the Polar regions back in time and thereby addressing which processes in the ocean and atmosphere that couple the climate of the North and South hemispheres and also which climate changes that are regional or global.

Based on many years of drilling experiences in Greenland, Centre for Ice and Climate has established a leading position in the drilling of ice cores as well as in the development of drilling equipment. Based on these experiences the Centre supports the project with the development and the supply of drilling equipment as well as the crew to be in charge of the drilling at Aurora Basin North.

The new developed drilling system is adapted the Danish made HT-drill – the Hans Tausen drill.

The new drilling system as well as the newly developed drilling fluid, ESTISOL 140, was tested in the NEEM camp in Greenland during the summer of 2012. Simon Sheldon (left) is the project engineer on the development of the drilling equipment and the fluid, and in November 2013 he left for ABN in the Antarctic to be in charge of setting up the Danish Intermediate Depth ice core drilling equipment and its associated infrastructure. (In the middle) Trevor Popp, associate professor at Centre for Ice and Climate, who has assisted in developing the new system. At (the) ABN Trevor Popp is going to be in charge of recovering the 400 meter long ice core together with Mark Curran from the Australian team. Carsten Mortensen (right) is a research technician at the Niels Bohr Institute and he has helped developing the mechanical parts for the new drilling system.

In September 2013 the Danish Hans Tausen drill was shipped to the Aurora Basin North in the Antarctic together with a newly developed controlling system. However, before the lid was closed on the shipment the drilling team at the Centre for Ice and Climate had worked intensively throughout 1 ½ year to make the drilling system and the fluid meet the requirements and demands of the IPICS´ and to adapt it to the special conditions that you find in the Antarctic.

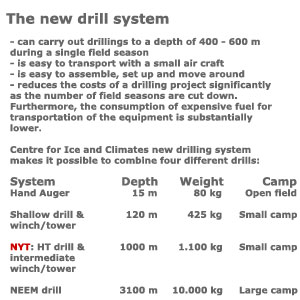

In 2004 IPICS wanted a new drilling system that would be able to recover ice cores of high qualities and to a depth of 1000 meters, but at a low cost. Centre for Ice and Climate has now produced it. And as an extra bonus the equipment is easy to transport, easy to maintain and easy to operate.

The HT drill is the Rolls Royce of the ice core drills, and throughout the years it has been copied by a number of nations. The latest to copy it was New Zealand who used the drill in the RICE project, which is ABN´s twin project. Because of the high standard and quality of the HT drill it is quite natural that the new drilling system has been developed to manage the HT drill.

Faster, easier and cheaper access to climate data

The drilling system consists roughly of a drill, a winch, an electronic control system and a tower.

At earlier intermediate ice core drillings, especially the winch and the tower have been the weak parts of the chain. The winch has been weak because it has been strained to the breaking point and the tower because its construction has required an inordinate amount of space and a lot of time to set up on the ice.

To be able to use the HT drill at intermediate drillings the drilling team of the centre has developed and produced a new system that will make it faster, easier and cheaper in the future to recover intermediate ice cores.

To be able to use the HT drill at intermediate drillings the drilling team of the centre has developed and produced a new system that will make it faster, easier and cheaper in the future to recover intermediate ice cores.

“It has been so much easier to operate the tower and it requires no major preparations. Earlier it was necessary first to dig a deep trench in order to operate the tower. We don´t have to do that no more. Now we can set up the tower on the ice very fast and start drilling at once. And with the newly developed winch that can carry a cable of more than 1000 meters and a pull of ½ ton we are able to hoist the HT drill faster up and down the borehole than was previously possible. It cuts significantly down on the total time spend on drilling”. Simon Sheldon continues visibly excited,

The famous CIC Hans Tausen drill mounted on the new system.In this view we can clearly see the drill head with 3 ice cutters. This is the business end of ice core drilling. While on the surface the HT drill is positioned horizontally so the ice core can be removed and the drill made ready for the next ice core drilling run.

The drill was developed by danish scientists in 1995, and it was named after a test drilling on the Hans Tausen ice cap on Peary Land in Greenland. Since then the drill has been used at a number of drillings in Greenland as well as in Antarctic, and has been copied by several other nations

“The new electronic control system has also been much easier to operate, without having to compromise on strength and precision. At the same time security is at the top for those to operate the system and it is easily maintained” says Simon Sheldon, who is the project engineer for the development and production of the new system and knows it inside out.

Simon Sheldon is one of the three from the centre who is going to the Antarctic. He will be in charge of setting up the drilling equipment and its associated infrastructure, and continuously make sure that the equipment functions according to the plan. Furthermore he will be measuring the borehole temperature profile.

New drill liquid

ESTISOL 140, a new developed drill liquid is being used in the Aurora Basin North drilling project. The liquid has a very low viscosity and is useable when drilling in temperatures as low as to -55 C.

The composition of the drill fluid is of great importance for the individual ice core as well as for the whole drilling process. Besides its importance for the quality of the ice cores it also ensures that the bore hole can withstand the growing pressure of the ice that arise the deeper the drill gets into the ice. And finally, the composition has to prevent the fluid from freezing at the very low temperatures.

“Another plus of the new drill liquid is that we don´t have to mix it with other liquids as we had to when drilling at NEEM. By using the same liquid all the way it is so much easier to do the drilling. This also makes it easier to work out precisely how much liquid we have to bring to the camp, which makes good sense when keeping the total costs down”, says Simon Sheldon, who has developed the new liquid in the laboratory in Copenhagen in 2011 and tested it in NEEM in 2012.

The drilling team from Centre for Ice and Climate is ready

The drilling team from Centre for Ice and Climate is ready

Many situations and problems that the drill and the drilling system may be exposed to under the extreme conditions in the Antarctic, has been thought trough during the preparations. If something is missing or breaks on the ice the team must manage with what they have. Because of this, a great part of the equipment that is packed in the basement of Centre for Ice and Climate consists of spares and replacements.

“It has been a huge challenge to produce the new system. The development began while the big ice core drilling project, NEEM was still operating and demanded attention. So, time to design and produce the new system to have it ready for the Aurora project has often been very pressed”, Simon Sheldon continues with a very satisfied smile on his face now as the two ton heavy equipment is packed and ready on a sledge on its way from the field station Dumont D´Urville and on its way to the Aurora camp 550 km further inland from the Antarctic coast.

ALSO READ

- North-South Climate Connections

- Centre people to Antarctic

- IPICS White paper - The IPICS 2k Array (pdf-file)

- IPICS White paper - Ice Core Drilling Technical Challenges (pdf-file)